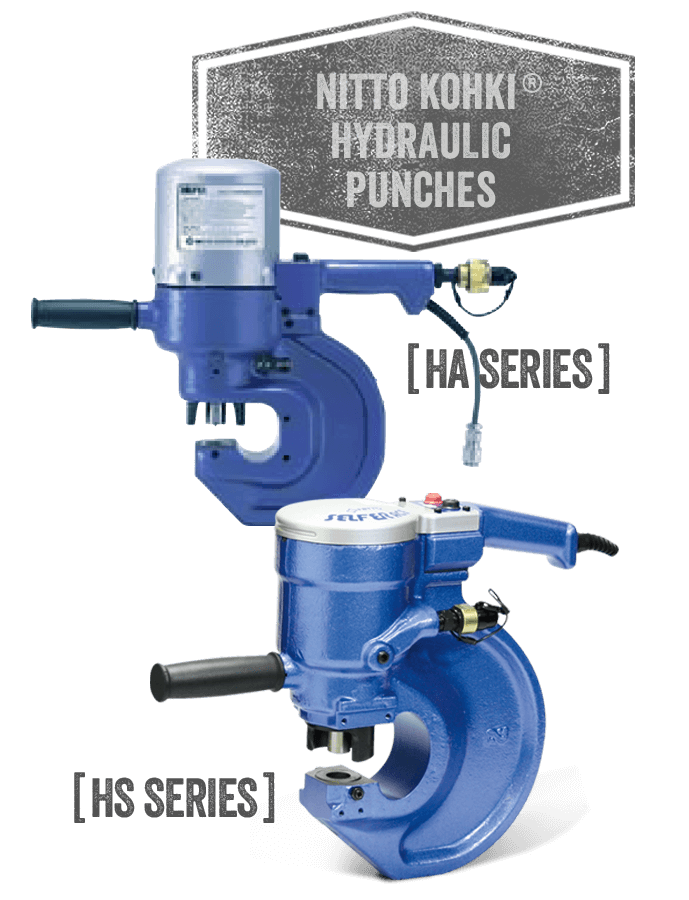

Our machine range is capable of quickly punching various special-shaped holes such as oval and round. It also includes a backup button that allows you to stop the punch instantly at any time. This single-acting hydraulic comes in a compact design, powered by a hydraulic engine. There are also manual and electronic hydraulic pump options.

Single-acting hydraulic punches can punch precise holes quickly and efficiently in a very short time. It has an automatic punch, returns and reset operation, which makes it suitable for many materials, including angle steel, channel and H-shapes steels and flat sheets (copper plate, aluminum and iron)